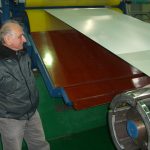

CCL – Coil Coating Line

We design CCL lines according to the customer requirements such as line speed, strip width (minimum maximum), strip thickness, coating quality and kind like polyester, epoxy etc.

The CCL line can galvanize steel strip coil, aluminum strip coil or both (together).

The CCL line can apply two coats & two bakes or three coats & three bakes.

A complete line can consist of the following items:

ENTRY SECTION:

- Two coil cars

- Two uncoilers

- Twin guillotine/cutter

- Joiner

- Tension (with two rolls)

- Accumulator (also known as looper) can be hydraulic or mechanic assisted.

- Drums (Depending of the line speed and maximum thickness of the strip can be 5-7-9 drums or more)

- Steering unit with two rolls

- Tension unit with two rolls

DEGREASING SECTION:

- First Cleaning

- Second cleaning

- Washing

- Squeezing

SURFACE PREPARATION & COATING SECTION

- Coater with Chromate free or Chromatizing unit

- Baking unit

- Tension unit with two rolls

- Steering unit with two rolls

- Primer Coater

- Oven conventional or near infrared unit

- Cooling unit

- Quenching unit

- Steering unit with two rolls

- Tension unit with two rolls

- Top Coater

- Oven conventional or Near Infra red

- Cooler

- Quenching unit

EXIT SECTION

- Looper

- Steering unit with two rolls

- Tensioning with two rolls

- Hydraulic cutting unit

- Recoiler

- Coil car